Automation's Impact on Manufacturing Operations

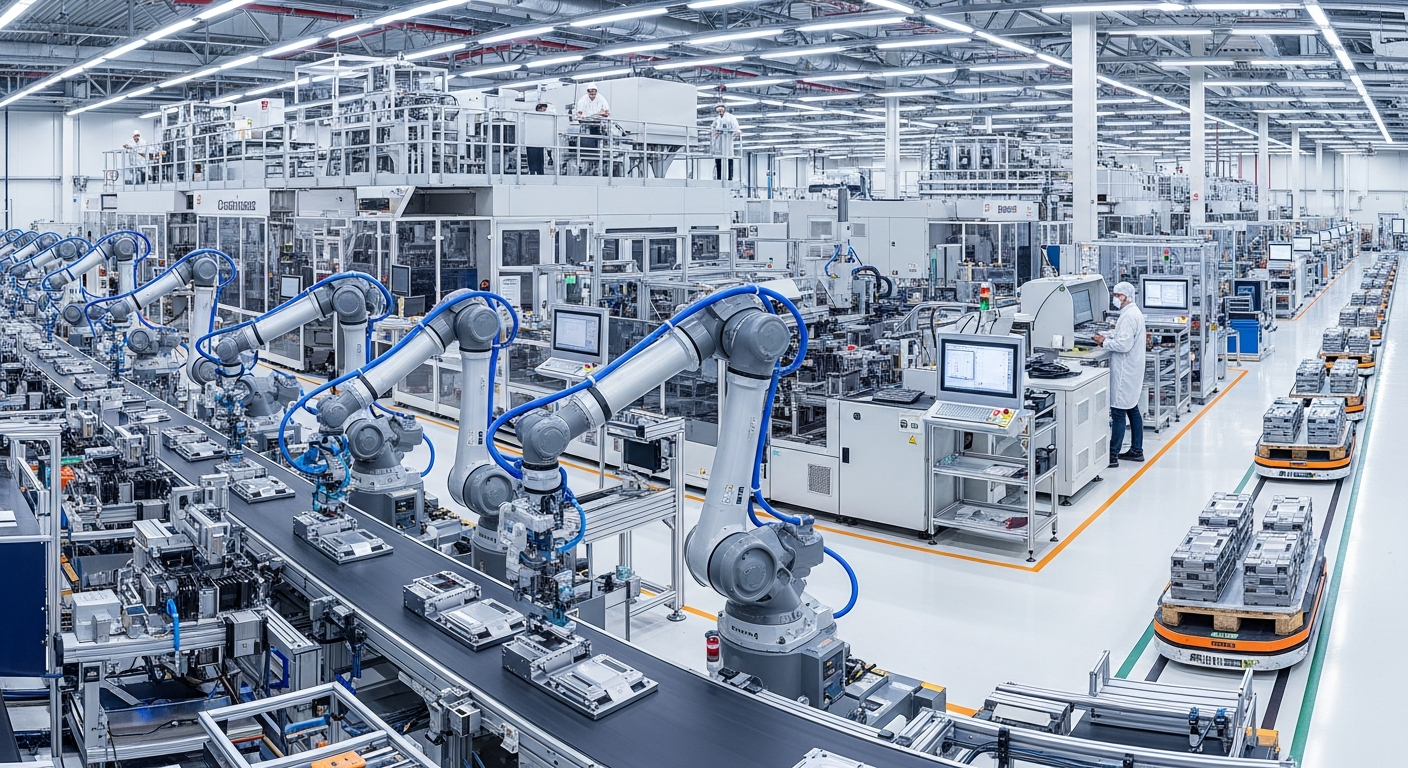

Automation technology has fundamentally reshaped manufacturing operations across various industries worldwide. By integrating advanced machinery, software, and artificial intelligence, businesses are achieving unprecedented levels of precision, speed, and consistency. This transformation extends beyond the factory floor, influencing everything from raw material acquisition to product delivery and overall enterprise strategy, driving a new era of industrial efficiency and innovation.

The landscape of global manufacturing has undergone a significant transformation due to the widespread adoption of automation. This technological evolution introduces sophisticated systems designed to streamline processes, enhance productivity, and reduce operational complexities. From discrete assembly lines to complex chemical processing, automation is becoming an indispensable component of modern production environments, fostering a competitive edge for enterprises navigating a dynamic market.

Enhancing Production and Efficiency through Automation

Automation plays a pivotal role in boosting production capabilities and overall operational efficiency within manufacturing. By automating repetitive or hazardous tasks, companies can achieve higher throughput rates, consistent product quality, and reduced human error. Robotic systems, for instance, can operate continuously, minimizing downtime and maximizing output. This not only accelerates the manufacturing process but also frees human workers to focus on more complex tasks requiring critical thinking, problem-solving, and innovation. The integration of advanced technology allows for real-time data collection and analysis, enabling quick adjustments to production lines and optimizing resource allocation.

Transforming Logistics and Supply Chain Management

Beyond the factory floor, automation significantly impacts logistics and the broader supply chain. Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) are increasingly common in warehouses, moving materials and finished goods with precision and speed. Automated storage and retrieval systems (AS/RS) optimize space utilization and inventory management, ensuring that components are available precisely when needed for production. This integration of automation across the supply chain enhances transparency, reduces lead times, and improves the overall responsiveness of the system, supporting efficient commerce and global distribution networks.

Strategic Implications for Enterprise Operations

For an enterprise, embracing automation is often a strategic decision with far-reaching implications. It allows companies to scale operations more effectively, adapt to fluctuating market demands, and maintain competitiveness in a globalized economy. Automation can reduce labor costs in certain areas while necessitating investment in new skill sets for managing and maintaining automated systems. This shift requires a comprehensive strategy that includes workforce training, cybersecurity measures, and a clear roadmap for technological integration. Ultimately, automation enables businesses to optimize their entire operational framework, from procurement to customer delivery, fostering long-term growth and resilience.

Driving Sustainability with Innovative Manufacturing Technology

Innovation in automation technology also contributes significantly to sustainability efforts in manufacturing. Optimized processes often lead to reduced waste, lower energy consumption, and more efficient use of raw materials. Predictive maintenance, enabled by automated monitoring systems, can prevent equipment failures, extending the lifespan of machinery and reducing the need for premature replacements. Furthermore, the ability to produce goods more efficiently and locally, through advanced automated techniques, can minimize transportation emissions. This alignment of technology with sustainability goals is crucial for businesses aiming to meet environmental targets and appeal to eco-conscious consumers.

Evaluating the Investment in Manufacturing Automation

Implementing automation technology involves a range of investment considerations, from initial hardware and software costs to ongoing maintenance and training. The scale and complexity of the automation solution significantly influence the overall expenditure. While specific costs vary widely, understanding typical benchmarks can help businesses plan their strategy.

| Product/Service | Provider Category | Cost Estimation (USD) |

|---|---|---|

| Basic Robotic Arm (single task) | Industrial Robotics Firms | $25,000 - $100,000+ per unit |

| Automated Guided Vehicle (AGV) | Logistics Automation | $15,000 - $150,000+ per unit |

| Manufacturing Execution System | Software Vendors | $50,000 - $500,000+ (software) |

| Full Smart Factory Integration | System Integrators | $1,000,000 - $10,000,000+ |

| Predictive Maintenance Software | AI/IoT Solutions | $5,000 - $50,000+ per year |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

In conclusion, automation stands as a transformative force in modern manufacturing, offering substantial benefits across production, logistics, and overall enterprise operations. Its capacity to enhance efficiency, drive innovation, and support sustainability initiatives positions it as a cornerstone for future industrial development. As technology continues to advance, the strategic adoption of automation will remain crucial for businesses seeking to thrive in a competitive and interconnected global market.